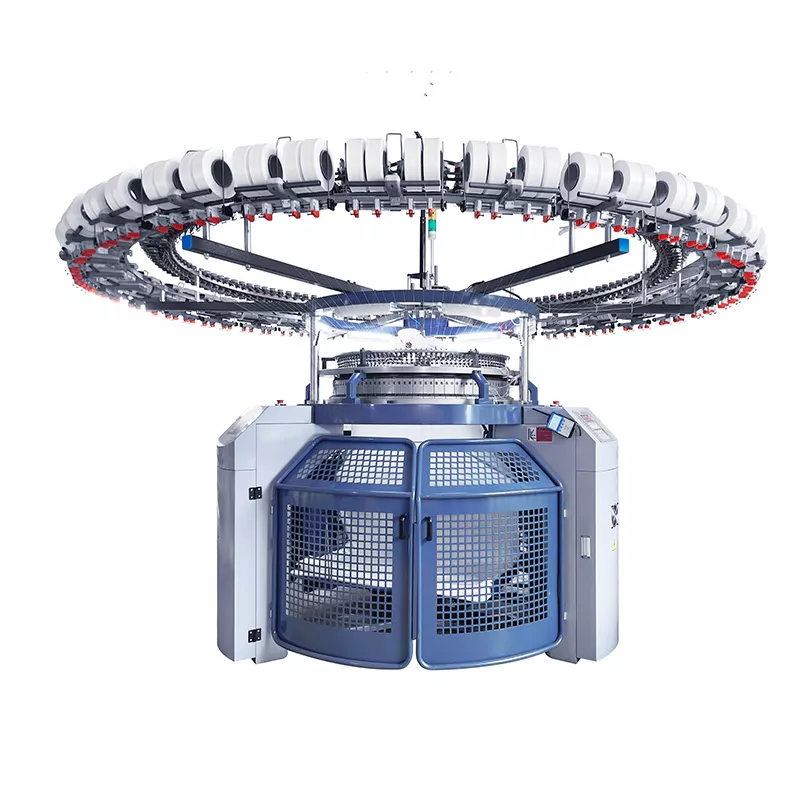

High Leg Single Jersey Circular Knitting Machine - Model HY-SO-H2 by HENGYE - Efficient, Versatile, High-Quality Fabric Production

PRODUCT SERIES: Single Jersey Knitting Machine

- Cylinder Diameter: 34"/38"/44" (inch)

- Gauge: 12G-50G

- Feeders: 32F-272F

- Knitting Style: Weft

- Speed: 16-35 RPM

- Power: 3.7-7.5KW

- Needle Style: Latch Needle

- Dimensions (L x W x H): 3.27m x 2.3m x 3.0m

- Fabric Output: 450 KG/DAY

- Production Capacity: 100 sets per month

- Origin: Manufactured in China, Quanzhou

- After-sales Service: On-Site Maintenance Available in Numerous Countries

Color:

-

Explore the capabilities of the High Leg Single Jersey Circular Knitting Machine, Model HY-SO-H2, crafted by HENGYE with advanced knitting technology to meet dynamic textile industry demands. This machine excels in efficiency, adaptability, and fabric quality, setting new standards in fabric production.

Features and Benefits:

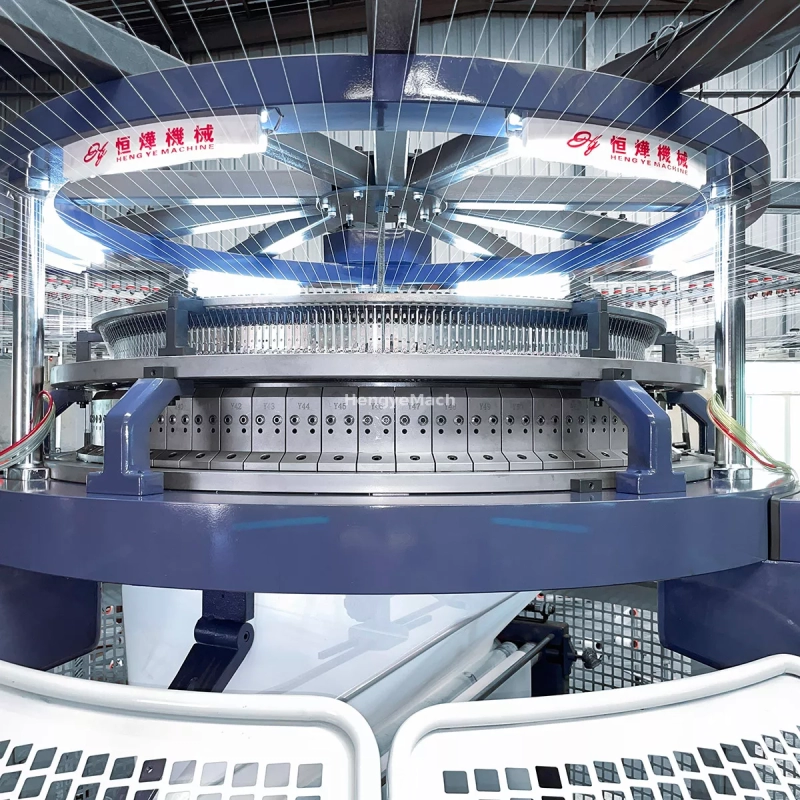

Optimized Fabric Production:

- Unique design ensures fabric remains flat post-knitting, minimizing additional handling processes and enhancing overall production efficiency.

Versatile Gauge Options:

- Multiple gauge options available based on cylinder diameter, catering to a wide range of fabric textures and strengths.

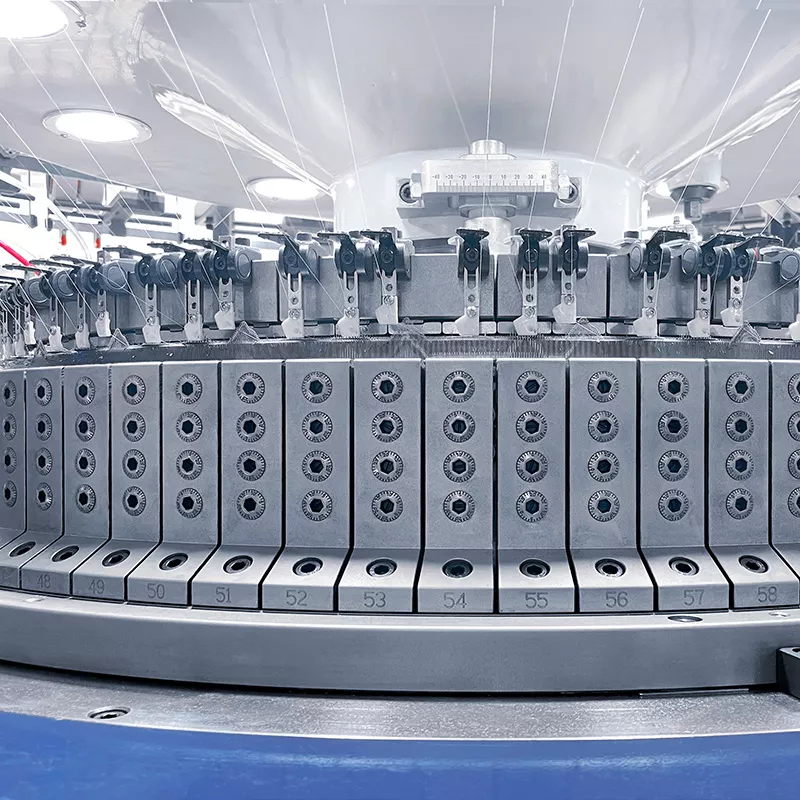

Innovative Needle Configurations:

- Flexibility in needle track configurations facilitates the production of diverse fabric types, allowing for experimentation with designs and textures.

State-of-the-Art Design Features:

- Modern design supports smooth yarn feeding, meeting high-speed weaving requirements and ensuring consistent fabric quality, including spandex integration.

Unmatched Versatility:

- Easy cylinder replacement and varied sinker triangle configurations enable production of various fabrics—from everyday wear to specialized textile applications.

Conclusion: The High Leg Single Jersey Circular Knitting Machine from HENGYE combines innovation, efficiency, and versatility, making it an indispensable asset for textile manufacturers. With its advanced features and capability to produce high-quality fabrics efficiently, it stands at the forefront of modern textile production technology.